He pilikia maʻamau ka Burrs i ka hana metala, e like me ka wili ʻana, ka huli ʻana, ka wili ʻana, a me ka ʻoki ʻana i ka metala...

ʻO kekahi o nā pōʻino o nā burrs ʻo ia ka maʻalahi o ka ʻoki ʻana!No ka wehe ʻana i nā burrs, pono ka hana lua i kapa ʻia ʻo deburring.Hiki i ka 3 deburring a me ka hoʻopau ʻana i nā ʻāpana kikoʻī ke helu no 30% o ke kumukūʻai o ka ʻāpana i hoʻopau ʻia.Eia kekahi, paʻakikī ka hoʻopau ʻana i nā hana hoʻopau lua, no laila ua lilo nā burrs i pilikia paʻakikī.

Pehea e hoʻoponopono aiBURRS

1 Hoʻopau lima lima

ʻO kēia kahi hana maʻamau a hoʻohana mau ʻia, me ka hoʻohana ʻana i nā faila (faila manual a me nā faila pneumatic), ke one, nā kāʻei kāʻei, nā poʻo wili, a me nā mea hana kōkua.

Disadvantags: He pipiʻi ke kumukūʻai hana, ʻaʻole kiʻekiʻe ka maikaʻi, a paʻakikī ke wehe i nā lua keʻa paʻakikī.

Nā mea pili: ʻAʻole kiʻekiʻe loa nā koi ʻenehana no nā limahana, a ua kūpono ia no ka hoʻoheheʻe ʻana i ka alumini alumini me nā burrs liʻiliʻi a me ke ʻano huahana maʻalahi.

2 Make deburring

Hana ʻia ka deburring me ka hoʻohana ʻana i kahi make make a me kahi kuʻi.

Nā pōʻino: Pono ia i kahi nui o ka make (make ʻino, make maikaʻi) ke kumukūʻai hana, a pono paha e hana i kahi make make.

Nā mea e pili ana: He kūpono ia no ka hoʻoheheʻe ʻana i ka alumini alumini me nā wahi hoʻokaʻawale maʻalahi, a ʻoi aku ka maikaʻi a me ka hopena deburring ma mua o ka hana lima.

3 Ka wili a me ka wehe ʻana

Aia kēia ʻano deburring i ka vibration, sandblasting, rollers, etc., a ke hoʻohana ʻia nei e nā mea kanu make.

Nā pōʻino: Aia kahi pilikia ʻaʻole maʻemaʻe loa ka wehe ʻana, a koi ʻia ka hana lima ma hope o nā koena burrs a i ʻole nā ʻano hana deburring.

Nā mea pili: kūpono no nā mea hoʻoheheʻe make alumini liʻiliʻi me nā pahu nui.

4 Hoʻopau hau

E hoʻohana i ka mea hoʻomaha no ka hoʻomaloʻo wikiwiki ʻana i nā burrs, a laila e pīpī i nā projectiles e wehe i nā burrs.ʻO ke kumukūʻai o nā mea hana ma kahi o 200,000 a i ʻole 300,000;

Nā mea pili: He kūpono no nā mea hoʻoheheʻe make alumini me ka mānoanoa pā liʻiliʻi burr a me ka leo liʻiliʻi.

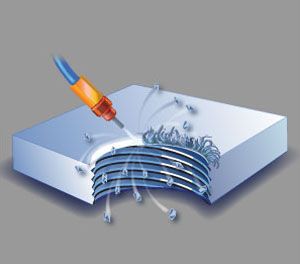

5 Wela blast deburring

Kapa ʻia hoʻi ka thermal deburring, explosion deburring.Ma ka hoʻokomo ʻana i kekahi kinoea lapalapa i loko o kahi umu ahi, a laila ma o ka hana ʻana o kekahi media a me nā kūlana, ua pahū koke ke kinoea, a hoʻohana ʻia ka ikehu i hana ʻia e ka pahū e hoʻoheheʻe a wehe i ka burr.

Nā pōʻino: nā lako waiwai (miliona kālā), nā koi ʻenehana kiʻekiʻe no ka hana, haʻahaʻa haʻahaʻa, nā hopena ʻaoʻao (rusting, deformation);

Nā mea pili: Hoʻohana nui ʻia i kekahi mau ʻāpana kikoʻī kiʻekiʻe, e like me nā kaʻa a me nā ʻāpana aerospace.

6 Hoʻopau i ka mīkini kalai

ʻAʻole nui ke kumukūʻai o nā mea hana (ʻumi tausani).

Nā mea pili: He kūpono ia no ka hoʻolālā ākea maʻalahi a me ke kūlana deburring maʻalahi a maʻamau.

7 Ka hoʻopau ʻana i nā mea kemika

Ke hoʻohana nei i ke kumu o ka hopena electrochemical, hiki i nā ʻāpana i hana ʻia me nā mea metala hiki ke hoʻopau maʻalahi a koho ʻia.

Nā mea pili: kūpono i nā burrs o loko i paʻakikī e wehe, kūpono i nā burrs liʻiliʻi (ka mānoanoa ma lalo o 7 mau uea) o nā huahana e like me nā kino pump a me nā kino valve.

8 Hoʻopau i ka electrolytic

ʻO kahi ʻano mīkini hana electrolytic no ka wehe ʻana i nā pahu hoʻoheheʻe alumini alumini e ka electrolysis.He kūpono ka deburring Electrolytic no ka wehe ʻana i nā burrs i nā ʻāpana huna o ka alumini alloy die castings, nā lua keʻa a i ʻole nā ʻāpana me nā ʻano paʻakikī.ʻOi aku ka maikaʻi o ka hana, a ʻo ka manawa deburring maʻamau he mau kekona wale nō a hiki i ʻumi kekona.

Nā pōʻino: He corrosive ka electrolyte i kekahi ʻano, a ʻo ka puni o ka burr o nā ʻāpana ke kau ʻia i ka electrolysis, e nalowale ka ʻili i kona luster kumu, a pili pū i ka pololei dimensional.Pono e hoʻomaʻemaʻe ʻia ka hoʻoheheʻe alumini alumini a pale ʻia ma hope o ka deburring.

Nā mea pili: He kūpono ia no ka hoʻopau ʻana i nā kaʻa, nā koʻokoʻo hoʻohui, nā kino valve a me nā lua alahele aila crankshaft, a me ka hoʻopuni ʻana i nā kihi ʻoi.

9 ʻO ka hoʻoheheʻe ʻana i ka wai jet kiʻekiʻe

Ke hoʻohana nei i ka wai ma ke ʻano he ʻano, hiki iā ia ke hoʻohana i kona ikaika hopena koke e wehe i nā burrs a me nā uila i hana ʻia ma hope o ka hana ʻana, a i ka manawa like, hiki iā ia ke hoʻokō i ke kumu o ka hoʻomaʻemaʻe.

Cons: ʻO nā mea kūʻai nui

Nā mea pili: hoʻohana nui ʻia i loko o ka puʻuwai o nā kaʻa a me nā ʻōnaehana mana hydraulic o nā mīkini hana.

10 Ultrasonic deburring

He mea paʻakikī ka hana ʻana i nā burr e like me nā lua.ʻO ke kaʻina hana maʻamau abrasive flow machining (ʻelua ʻaoʻao kahe) e hoʻokuke i ka abrasive ma o ʻelua mau puʻupuʻu abrasive kūʻē kū pololei e hoʻoheheʻe ʻia i hope a i waho i ke kahawai i hana ʻia e ka mea hana a me ka mea hoʻopili.ʻO ke komo ʻana a me ke kahe ʻana o ka mea abrasive i loko a ma o kēlā me kēia wahi i kaupalena ʻia e hana i kahi hopena abrasive.Hoʻomaluʻia ke kaomi extrusion ma 7-200bar (100-3000 psi), kūpono no nā hahau likeʻole a me nā manawa pōʻai likeʻole.

Nā mea pili: Hiki iā ia ke hoʻopaʻa i nā burrs microporous 0.35mm, ʻaʻole i hana ʻia nā burrs lua, a hiki i nā ʻano wai ke mālama i nā burrs kūlana paʻakikī.

11 Abrasive kahe deburring

He mea paʻakikī ka hana ʻana i nā burr e like me nā lua.ʻO ke kaʻina hana maʻamau abrasive flow machining (ʻelua ʻaoʻao kahe) e hoʻokuke i ka abrasive ma o ʻelua mau puʻupuʻu abrasive kūʻē kū pololei e hoʻoheheʻe ʻia i hope a i waho i ke kahawai i hana ʻia e ka mea hana a me ka mea hoʻopili.ʻO ke komo ʻana a me ke kahe ʻana o ka mea abrasive i loko a ma o kēlā me kēia wahi i kaupalena ʻia e hana i kahi hopena abrasive.Hoʻomaluʻia ke kaomi extrusion ma 7-200bar (100-3000 psi), kūpono no nā hahau likeʻole a me nā manawa pōʻai likeʻole.

Nā mea pili: Hiki iā ia ke hoʻopaʻa i nā burrs microporous 0.35mm, ʻaʻole i hana ʻia nā burrs lua, a hiki i nā ʻano wai ke mālama i nā burrs kūlana paʻakikī.

12 ʻO ka hoʻopau ʻana i ka magnetic

ʻO ka wili magnetic ʻo ia ma lalo o ka hana a kahi māla magnetic ikaika, ua hoʻonohonoho ʻia nā abrasives magnetic i hoʻopiha ʻia i loko o ke kahua magnetic ma ke ala o nā laina kahua magnetic, adsorbed ma nā pole magnetic e hana i nā "abrasive brushes", a hoʻoulu i kekahi kaomi ma luna. ka ʻili o ka mea hana, a ke hoʻokele nei nā pole magnetic i nā "abrasives".ʻOiai ke kaʻapuni ʻana o ka pulupulu, mālama ia i kahi āpau a neʻe ma ka ʻili o ka mea hana, i ʻike ai i ka pau ʻana o ka ʻili o ka mea hana.

Nā hiʻohiʻona: ke kumukūʻai haʻahaʻa, ka laulā hana ākea, ka hana maʻalahi

Nā mea hana: grindstone, magnetic field strength, workpiece speed, etc.

13 Huina wili lopako

Ua like ke kumumanaʻo me ka manual deburring, koe wale nō ka hoʻololi ʻana o ka mana i robot.Me ke kākoʻo o ka ʻenehana hoʻolālā a me ka ʻenehana hoʻokele ikaika, ʻike ʻia ka wili maʻalahi (ka hoʻololi ʻana o ke kaomi a me ka wikiwiki), a ʻike ʻia nā pono o ka robot deburring.

Ke hoʻohālikelike ʻia me nā kānaka, loaʻa i nā robots nā hiʻohiʻona: hoʻomaikaʻi maikaʻi, hoʻomaikaʻi maikaʻi, a me ke kumukūʻai kiʻekiʻe

Burrs ma nā ʻāpana Milled Challenge Special

Ma nā ʻāpana wili, ʻoi aku ka paʻakikī a ʻoi aku ka pipiʻi o ka deburring, no ka mea, ua hoʻokumu ʻia nā burrs he nui ma nā wahi like ʻole o nā nui like ʻole.ʻO kēia kahi e koho ai i nā ʻāpana kaʻina hana kūpono e hōʻemi i ka nui burr e lilo i mea nui.

Ka manawa hoʻouna: Sep-29-2022